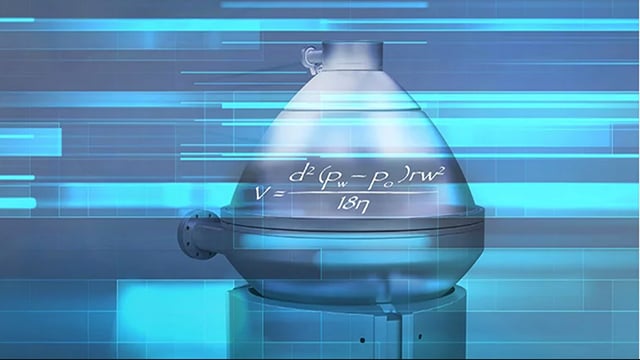

BB and BM Series

The BB and BM Series is the market’s most advanced series for bacteria and spore removal in the dairy industry. They feature patented Alfa Laval technologies that ensure efficient, reliable, and cost-saving separation.

Advanced technology for milk bactofugation

- Alfa Laval’s unique bottom-fed Hermetic Design provides superior skimming efficiency and maintains premium product quality

- The bottom-fed design reduces shear forces for gentle product treatment that preserves the size of the fat globules

- Hermetic seals on inlet and outlet prevent oxidation and reduce the foaming of the milk

- Easy adaptation to process conditions provides increased production flexibility and efficient CIP

- Energy savings of up to 60% thanks to the Hermetic Design

Alfa Laval sets the market standard with the Bactofuge® design

The BB and BM Series feature our patented Bactofuge® technology. These separators can be used for pre-treating cheese milk, where butter acid spores (anaerobic spores) are removed. They are also used to enhance the quality of milk powders, consumption milk and cream, thanks to the efficient removal of aerobic spores such as Bacillus cereus. Separation efficiency (defined as the percentage of the reduction of incoming level of bacteria and spores) can often reach up to 99%. For installations with particularly high demands, two or more units can be installed in series. The addition of unique features such as Alfa Laval eMotion™ and our bottom-fed, Hermetic Design also ensure high energy efficiency, compliance with the strictest hygienic standards and very low total cost of ownership.

Features that make the difference

What sets Alfa Laval separators apart is what’s on the inside: a broad scope of unique and patented technologies that, taken together, help dairy customers achieve improved product quality along with superior hygienic confidence. They also make it possible to drastically decrease both water and energy consumption, reducing both operational costs and environmental footprint.

Hermetic Design™

Gentle acceleration, powerful efficiency

A unique air-tight bowl that enables improved product quality and drastically reduces power consumption.

eDrive™

Mechanical simplicity for higher efficiency and lower costs

A direct-drive system with fewer rotating parts that minimizes both maintenance and energy costs.

UniDisc™

New levels of capacity and hygiene

A radical new disc design that decreases cleaning needs while increasing flow rate by up to 20%.

eMotion™

Double the output per kWh

An innovation to minimize friction, which cuts the separator´s energy consumption and CO2 footprint by up to 70%.

Bactofuge®

Outstanding solids capacity

Continuous solid discharge ensures an intact and highly concentrated stream for onward processing or as a valuable by-product. This makes it possible to increase separation capacity.

The Separator Innovator

Alfa Laval invented the first disc stack separator over a century ago. Since then, we have led the way by constantly improving and reinventing centrifuge technology. Making it safer, more efficient, and more sustainable. Visit our Separator Innovator knowledge base and discover how we continue to revolutionize separation processes across industries.